When Lindsey Pegram, a master’s candidate in environmental science and engineering at UNC-Chapel Hill, was growing up, she was surrounded by tools and heavy equipment. Her father, a successful general contractor specializing in home remodeling, was as busy building things around the house as he was for his customers in Greensboro and the surrounding area. But Pegram never touched so much as a hammer. Fluent in French and Spanish, she dreamt of traveling to countries like Brazil and Ghana to help marginalized communities with sanitation and clean water projects.

On a tour of admitted students in 2019, however, Pegram was shown a BeAM makerspace in Murray Hall and was immediately fascinated by the array of equipment—the 3D printer, which can be programmed to create wildly inventive shapes out of plastic or resin; the laser cutter to etch materials like fabric or wood and cut through plastic, acrylic and cardboard; an electronics section with racks of parts. Sewing machines. Drill presses. A router.

“I remember being fascinated with all the tools and eager to learn how to use them myself,” said Pegram. “The prospect of being part of BeAM heavily influenced my decision to come to UNC-Chapel Hill. I was eager to complete as many trainings as I could upon my arrival.”

As part of a first-year course, Experiencing Latin America, she used the makerspace in Carmichael Hall to create a jacket with an embroidered American flag, in which she replaced the stars with hand-drawn vectors of all the countries in Latin America and South America as a homage to U.S. immigration from those regions. At the bottom of the jacket, she hand-embroidered Todos Somos Americanos—“We are all American”—to stand in solidarity with those who trek through forbidding terrain on their way to the United States and then must navigate the U.S. immigration process.

“It was so intimidating at first; I didn’t want to mess anything up,” said Pegram. “These are really fancy machines, and it was hard for me, being a perfectionist, to accept that sometimes you’re going to break one and that you have to fix it. BeAM teaches you that failure is part of the learning process.”

After completing the project in which she received an A, she was hired as a program assistant in the Murray Hall makerspace where she was introduced to Howard Mendlovitz, a chemical engineer in the Martens Lab in the Department of Earth, Marine and Environmental Sciences. Mendlovitz frequently uses the makerspace, which is downstairs from his office, to custom-make instruments and create prototypes of valving systems that he uses in sensors that measure the amount of methane and microbial activity at the bottom of the ocean as part of an NSF-funded project.

“To have BeAM here on campus is a fantastic resource,” he said, “but the people there, like Lindsey and Lilia, are just as important as the equipment.”

One day, Mendlovitz broached the idea of using BeAM in the field to facilitate research for a variety of disciplines with Kenneth Langley, director of the BeAM program. To test the idea, Menelovitz offered to take two students on a research vessel in October whose primary mission was to retrieve one of the sensors and collect samples of seawater on the ocean floor a hundred miles off the Virginia coast. Pegram and Lilia Su, an undergraduate statistics major, were selected for the expedition.

The students’ objective during the three-day expedition was to investigate how they could operate makerspace equipment and assist the researchers aboard the vessel, especially in an uncontrolled and unpredictable environment.

“This was a perfect opportunity for testing the capacity of our equipment in the field,” said Langley. “There’s no Walmart floating out in the Atlantic.”

Pegram and Su packed consumables, basic hand tools, a 3D printer and filament, PETG plastic known for its versatility, drills, bits and a digital die-cutting Cricut machine. Once out on the ocean, they anticipated that the boat’s movement and the humidity would impede the function of the 3D printer, but were surprised to find that the dry lab, which housed the equipment, was well-equipped to handle the boat’s gentle rocking.

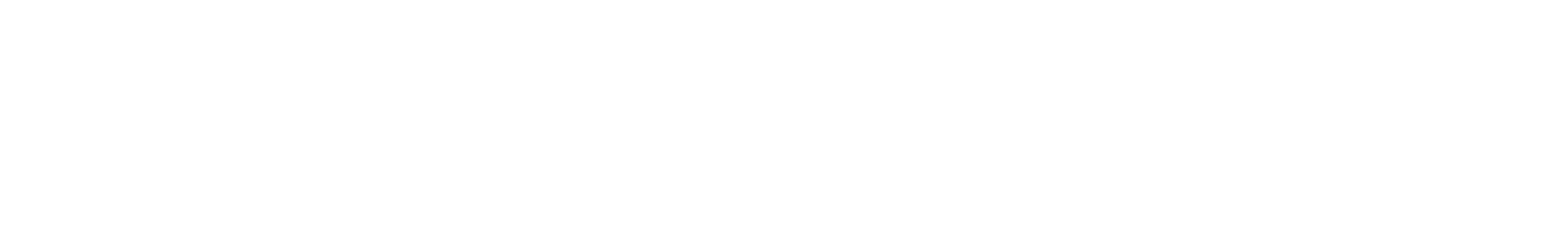

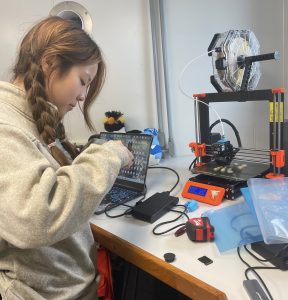

Members of the crew asked Pegram and Su if they could help them replace deck plugs that had been stripped and were hard to remove. The crew requested a smaller-diameter plug to account for deck expansion in the summer and that it have a square head, instead of the original quarter-size slit used in the original design. Pegram and Su, who is an experienced maker but had never designed a 3D model in a CAD program, went to work.

Upon launching the software, they discovered that they couldn’t verify and update the Fusion 360 software since they were beyond the reach of WIFI. To work around it, Su used Fusion’s pre-set thread options to aid her in designing a new plug. After a few trials, they were able to print 45 plastic deck plugs using a biodegradable filament.

“Since we didn’t remember to ensure the proper function of the software before embarking on the voyage, the program didn’t work as well as it could have,” said Su, “but one of our tasks was to make a list of essential materials, instrumentation and tools to avoid disruptions next time.”

The blending of technology and craft in tools, like 3D printers and laser cutters, has made it possible for UNC-Chapel Hill students to make extraordinary things, be it for fun, for art or for entrepreneurship, and the network of BeAM makerspaces on campus has attracted a devoted following. For Pegram and Su, the creation of the deck plugs for Mendlovitz’s crew gave them a sense of pride and ownership.

“BeAM is a place to learn, a place to grow, a place to incorporate human-centered design in making things and figuring out a problem,” said Pegram. “It might take 10 or 12 tries, but this is the place to do it.”

By Dave DeFusco, BeAM and the Department of Applied Physical Sciences